Unicut’s high manufacturing quality standards support customers wanting production of minute, often very complex, parts, prototypes and pre-production components that range from batch sizes of 25 to continuous production. The rigidity of our CNC machines ensures we can produce a vast array of precision-engineered components and features to a tolerance band of +/-2 microns (+/-0.002mm). Our CNC technology allows us to hold these tolerance bands on components up to a maximum length of 600mm.

Capabilities

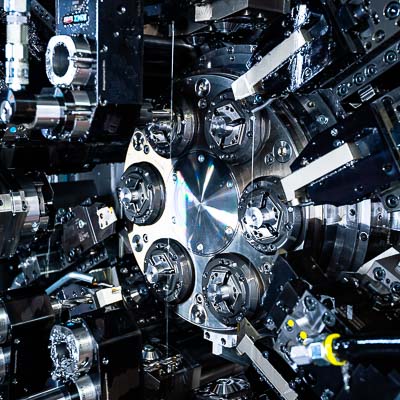

Fixed Head CNC Turning

Parts machined on the most rigid, robust and accurate turning centres the machine tool industry has available.

Multi-Spindle CNC Turning

For high volume, high quality components we’ve got it covered with the latest Index MS 40 Multi-Spindle.

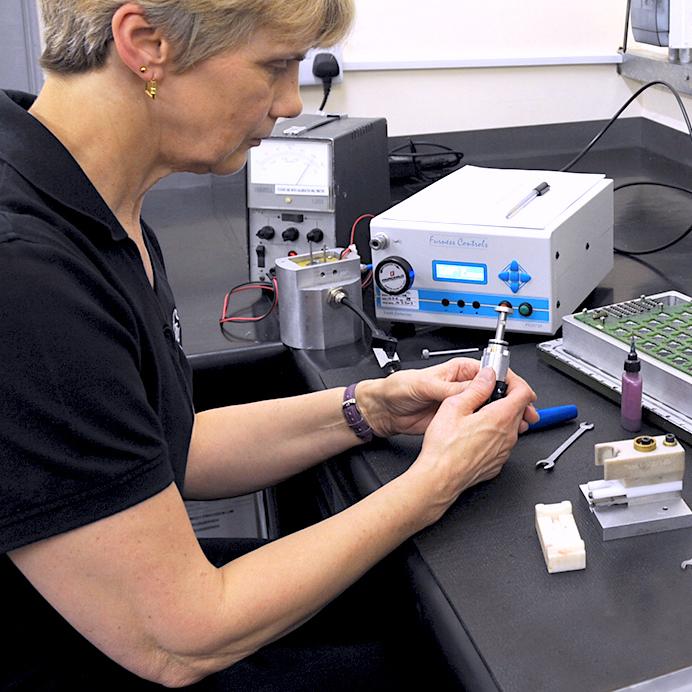

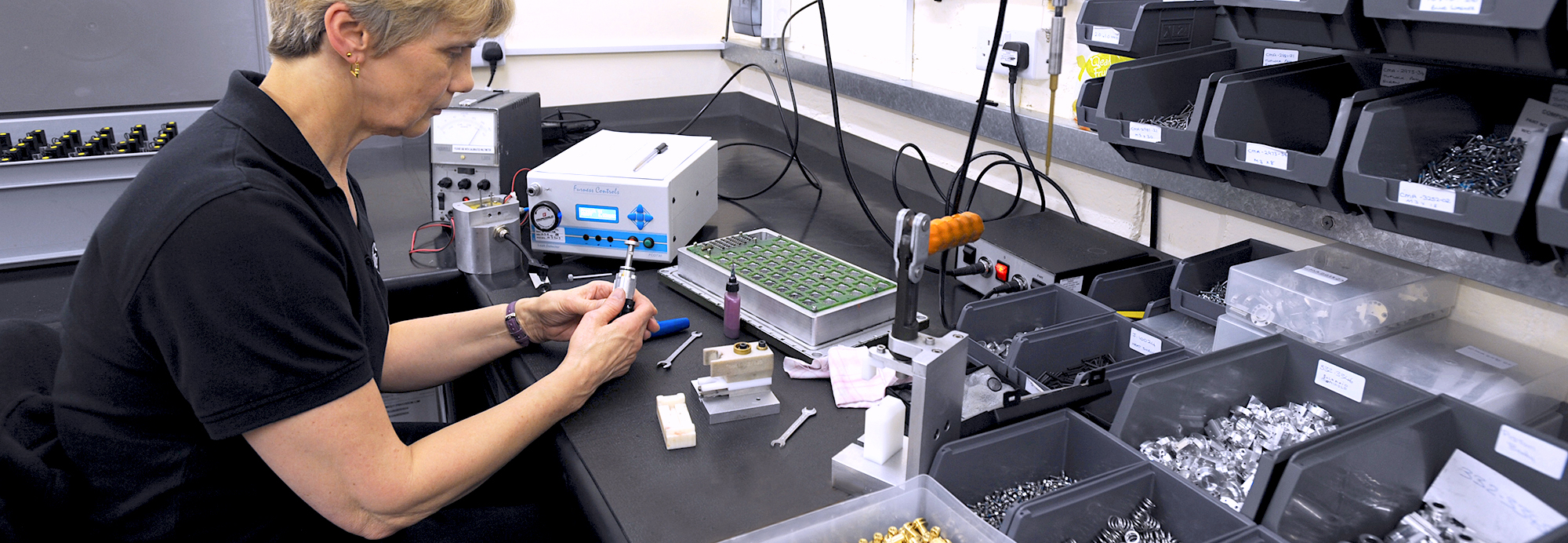

Assembly

Full or sub-assembly of components, back pressure and leak testing to ensure your parts exceed all quality expectations.

Milling – Up to 5 Axis

Three 5-Axis machining centres fitted with 160 tool magazines, laser tool measurement and component probing system.

Sliding Head CNC Turning

18 Citizen sliding head CNC turning centres manufacturing components for a range of clients and industries.

Materials

We work with more than a dozen of different metals and alloys, as well as engineering plastics.

Fixed Head CNC Mill/Turn Centres

Unicut have a series of fixed head CNC mill/turn centres, that offer our customers parts manufacture machined on the most rigid, robust and accurate turning centres the machine tool industry has available. We have invested heavily in the latest Miyano, Index and Mazak technology.

Optimising the ‘one-hit’ (single process) machining philosophy, these high specification CNC mill/turn centres incorporate two spindles for simultaneous front and back end working, three tooling turrets with 72 tool stations, with up to 36 driven tool stations, plus 15kw motors for maximum material removal rates. Built upon the most robust base, with remarkable thermal stability, high quality surface finishes are a given. These rigid machine tool designs also deliver exceptional accuracy levels that are qualified with on-machine probing and measurement of the components and cutting tools.

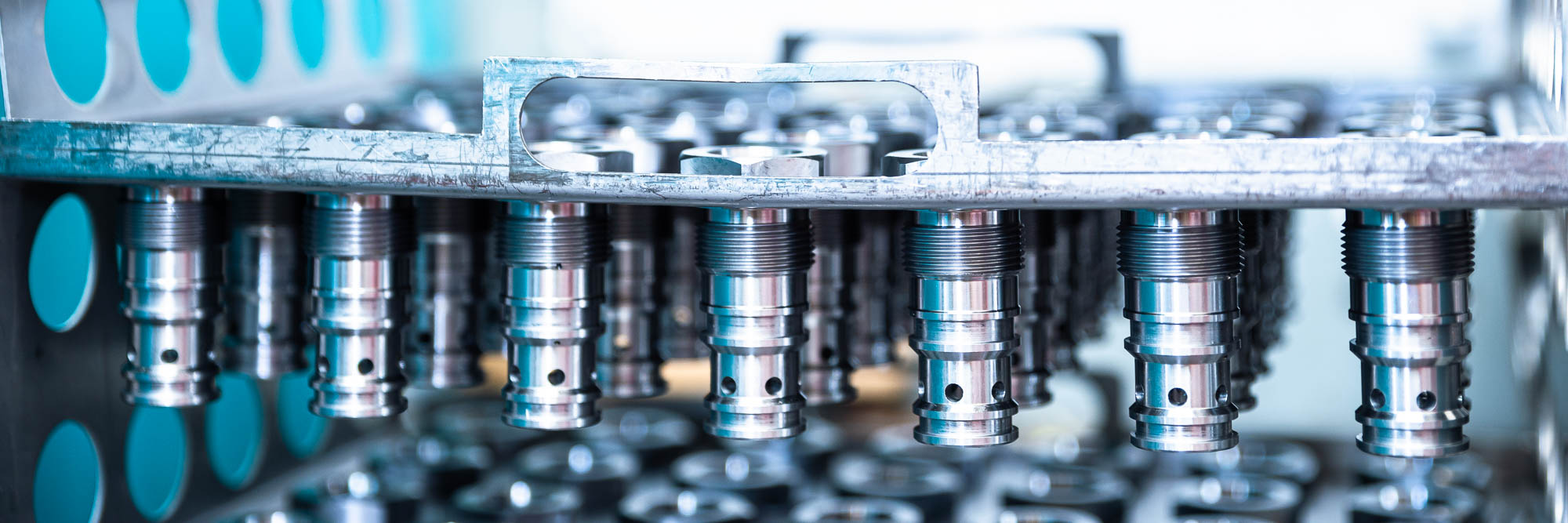

Multi-Spindle CNC Turning

For high volume, high quality components we’ve got it covered with the latest Index MS 40 Multi-Spindle. With 40 over axis machining simultaneously the versatility of the machine is vast, whether it’s simple or complex almost anything is possible. These machines are precise, fast, and flexible, coupled with an Imeca bar loading system capable of holding nearly 1 tonne of material, making volume parts has never been more dynamic. Temperature controlled Hydrostatic slides and ridged Hieth coupling index drum housing the 6 spindles independent programmable spindles make this machine ridged and accurate. This is the modern way to produce volume parts with CNC machined quality.

Sliding Head CNC Turning Centres

The flexibility, capability and capacity of our CNC machinery ensures Unicut can offer bespoke precision CNC engineering services and manufacture high specification components to suit almost all needs.

Unicut’s precision engineering facilities incorporates 18 Citizen sliding head CNC turning centres, manufacturing simple and complex components for a range of clients and industries.

The Citizen turning centres offer different diameter ranges:

• 4 machines have a turning capacity up to 12mm diameter

• 10 machines have a capacity up to 20mm diameter

• 4 machines up to 32mm capacity

With these machines grouped in cells to focus on particular component sizes, Unicut streamlines productivity and scheduling to guarantee Just-in-Time delivery.

The range of machine models gives great flexibility for low and high volume production, with up to 13-axis machining and C-axis on both main & sub-spindles.

Additionally, the sliding head machines can accommodate an impressive 80 cutting tools, with up to 14 driven tools and high pressure coolant up to 2000psi. These innovative machine tools enable our engineers to manufacture simple or highly complex components in small, medium or large scale production batch runs.

For more information on Unicut’s Sliding Head CNC Turning Centres, complete our quick enquiry form, call us on +44 (0) 1707 331227 or email sales@unicutprecision.co.uk

5-axis CNC Mill Centres

With three top of the range Mazak VARIAXIS i-600 5 -Axis Mill Machines no prismatic job out of our reach. These ridged 5-Axis machining centres are each fitted with a 160 tool magazine, laser tool measurement and component probing system to ensure quality is right first time.

Coupled to the latest Mazak Palletech FMS Pallet System with 48 pallets supports full light out unattended lights out production. All pallets are equipped with zero point fixture fast change overs.

Assembly

As a customer driven business, we constantly work as a solution provider. Therefore, we have an established and dedicated assembly department to enable Unicut to provide a complete service to our customers. Our assembly team works in a clean room environment that allows us to conduct full or sub-assembly of customer components, in an environment conducive to providing impeccable quality levels. We have the facility to conduct back pressure and leak testing for pneumatic and hydraulic assemblies to guarantee 100% calibration levels. Additionally, we have a vast array of jigs, fixtures and testing equipment to ensure our customers’ component assemblies exceed all quality expectations.

We also provide our customers with a bagging or packaging service, to allow the products we manufacture and assemble to be delivered in standard or customer designed packaging. Unicut’s pack and dispatch resource provides a premium service to our customers, adhering to delivery times and packed appropriately as required – a complete ‘concept to component/assembly’ service.

Delivery/Supply Chain

In the market we operate in, ‘on time delivery’ is not only vital but essential for keeping production lines running without disruption. As a totally dedicated customer driven business, Unicut has built a reputation for total reliability across a wide range of industry sectors and blue chip companies. To allow us to build upon this reputation, we have implemented a number of systems to further guarantee a continuous supply chain. We have for some time operated production supply philosophies, such as Just-in-Time (JIT) and Kanban, to ensure our customers have their parts when and where they are required.

As part of our delivery and supply chain service, we provide consignment stock when required, with maximum and minimum quantity levels to suit the end users’ production scheduling. Taking this service a step further, we offer consignment stock that can be held either at the customer facility or at Unicut, to maximise the customer’s floor space.

The efficiency of this service enables us to provide a next day delivery service for orders placed before 4pm.

Materials

The range of materials we work with includes:

Aluminium

Steel

Aluminium Bronze

Invar (Nickel-Iron alloy)

Peek

Titanium

Copper

Brass

Inconel

Acetal

Standard Duplex Stainless Steel

Super Duplex Stainless Steel

Martensitic Stainless Steel

Phospor Bronze

Delrin

Should you wish to discuss futher material options and suitability, please contact us.